ATLAS

Level-1Trigger

The jFEX Module

– draft

–

Project Specification

Version 0.0

Date: 08/08/2013 14:36:26

Bruno, Stefan, Uli

Universität Mainz

1.2.4 Configuration, monitoring, and

control

Pre-configuration access / ATCA

compliant slow control

3.4 Board level issues: signal

integrity, power supplies, and line impedances

4 Firmware, on-line software and tests

4.1 Service- and infrastructure

firmware

5 Interfaces : connectors, pinouts,

data formats

5.3 Backplane connector layout

5.4 Interfaces to external systems

6 Appendix -- will move to separate document?!?!?

6.1 Checklist for detailed design

1

Introduction

This document

describes the specification for the Level-1 jet feature extractor module

(jFEX). Section 1 of this document gives an overview of the module. Section 2

describes the functional requirements. Section 3 details the implementation.

Section 5 summarizes the external interfaces.

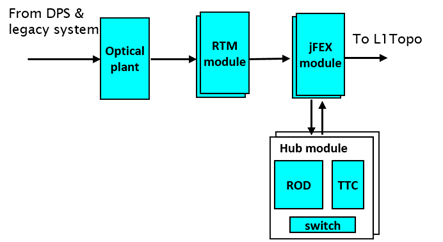

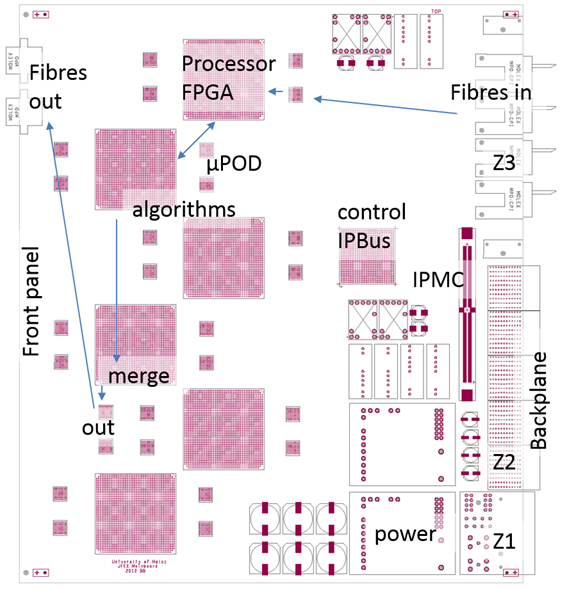

Figure 1 : The jFEX

system

1.1

Related projects

The jFEX system is a

major processor system within the ATLAS Level-1 calorimeter trigger. The jFEX

system will replace the current jet and energy sum trigger (JEP) in run 3. It

will find jets and large taus and will calculate energy sums. The jFEX system

consists of a single ATCA shelf of electronic modules (blades), eight jFEX

modules, and two hub modules. The jFEX system also comprises the real-time

input stage: optical fibre plant and rear-transition modules. The jFEX system

is shown in Figure 1. It will share a large fraction of modules

with the eFEX system. The jFEX module interfaces to a large number of modules

and systems.

Phase-0 L1Calo modules http://hepwww.rl.ac.uk/Atlas-L1/Modules/Modules.html

L1Topo

Hub

ROD

eFEX

1.2

The jFEX processor module

The jFEX processor

module is an AdvancedTCA (ATCA) module. The baseline design requires eight

modules in a single ATCA shelf. Each jFEX module determines jets and taus

within an octant of the ATLAS calorimeters, calculates partial energy sums

within the octant and sends the results to the topology processor L1Topo. The

jFEX module covers the whole eta range and the respective calorimeter systems:

FCALs, end caps and barrel. Environment data required for the jet and tau

algorithms is received from neighbouring octants on separate fibres, duplicated

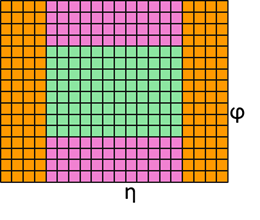

at source (see Figure

2, a section in eta is shown, cf. 1.2.2).

Figure 2 : jFEX core (green) and environment data

duplicated at source (magenta) and sink (orange)

1.2.1

Baseline algorithms

The jFEX is in charge of finding localized objects in the incoming

calorimeter data, jets and large taus. Furthermore it calculates global

quantities, the total and the missing transverse energy. The energy summation

is performed in segments of the calorimeters separately, to generate data that

can be used for pile-up corrections on the topology processor. The processors

operate on separate electromagnetic and hadronic trigger towers at a granularity

of 0.1 x 0.1 in eta x phi.

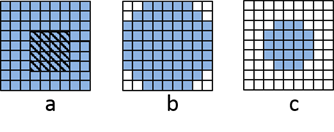

The baseline jet and tau algorithms are sliding window algorithms

operating on pre-summed electromagnetic + hadronic trigger towers within an

environment of 0.9 x 0.9 in eta and phi. That limits the maximum jet size to a

radius of 0.45. An advanced option capable of doubling the jet cone size is

discussed in a separate document. Within the limitations of environment

available to each “core” cell, the definition of a “jet” is flexible. Figure

3a shows a jet definition with ROI (hatched) in

use in run 1, though with higher granularity and slightly increased environment

(blue). Taus are identified within smaller cones.

Figure 3 : jet

algorithms

1.2.2

Real-time data path

ATCA Backplane zone 3

of the jFEX is used for real-time data transmission. The input data enter the

jFEX optically through the backplane. The fibres are fed via four optical

backplane connectors that carry 72 fibres each. The optical signals are

converted to electrical signals in 12-fibre receivers. The electrical

high-speed signals (6.4 Gb/s line rate) are routed into six FPGAs, where they

are de-serialised in MGT receivers; the parallel data are presented to the FPGA

fabric. The processor FPGAs operate on their input data independently and in

parallel. They process a calorimeter “core” area of 1.2 x 0.8 in eta x phi each

and require an additional processing environment of 0.4 to either side.

Therefore a single FPGA will operate on a 2.0 x 1.6 area worth of input data.

Figure 4 shows a conceptual drawing of the jFEX. The real-time processor FPGAs

are labelled A to F. They are surrounded by the optical receivers.

Non-real-time module control functionality is implemented on FPGA K, as well as

on mezzanine modules (IPMC module I, extension mezzanine). More detailed

diagrams are shown in section 3.

![]()

I

Figure 4: the jFEX module

Data

reception

The optical data arrive

on the main board on 12-fibre ribbons. Since the backplane connectors support

multiples of 12 fibres, the optical signals will be routed via “octopus” cable

sets, splitting 72 fibres into groups of 12. The opto-electrical conversion

will be performed in Avago MicroPOD 12-channel devices. The opto receivers

exhibit programmable pre-emphasis so as to allow for improvement on signal

integrity for given track length.

After just a few

centimetres of electrical trace length, the multi-gigabit signals are

de-serialised in the processor FPGAs. They allow for programmable signal

equalization on their inputs. The exact data formats are as yet undefined,

though standard 8b/10b encoding is envisaged for purpose of run length

limitation and DC balance. The processors are supplied with required bias and

termination voltages, as well as suitable reference clocks.

Data

duplication

Data sharing between

neighbouring FPGAs is accomplished by “PMA loopback”, a scheme that splits a

duplicated signal from the incoming data early on in the MGT data path and

sends it out of the transmitter section of the same high-speed channel. There

is a latency penalty of about one LHC bunch clock associated to this

duplication scheme. The data duplicated by PMA loopback are shown in orange

colour in Figure 2.

Data processing

The jet and tau

algorithms, as well as energy summation are performed on the processor FPGAs

for a core area of 1.2 x 0.8 each. All calculations for all “sliding” windows

with an offset of 0.1 in eta and phi are computed concurrently. The jets are

disambiguated within each FPGA, double counting of objects overlapping between

neighbouring FPGAs are avoided by determination of relative maxima of energy

deposition, including the environment data. Resulting jet candidates are

reported on parallel fabric I/O and fed into the merger FPGA which both finds

objects within its own calorimeter area and consolidates results from the other

processor FPGAs.

Energy sums (Et,

Etmiss) are determined within a processor FPGA and are consolidated on the merger

FPGA. In addition, eta projections of the total energy sums are calculated

separately so as to allow for pile-up corrections downstream, on the L1Topo

processor.

The merger FPGA

reports the localized objects as well as global quantities to the L1Topo

processor. It is able to supply data to up to 3 topology processors, on a total

of 24 optical fibres.

1.2.3

Clock

distribution

The operation of the

real-time data path requires low-jitter clocks throughout the system. For

synchronous operation, data transmitters will have to be operated with clean

multiples of the LHC bunch clock. Receiver reference clocks may as well be

derived from local crystal oscillators, though tight limits on the frequency

range will have to be observed. The jFEX module will be designed for 40.08 MHz

operation of the real-time data path only.

The fabric clocks run

at the LHC bunch clock frequency. The MGTs are clocked off multiples of the LHC

clock. The jitter on the MGT bunch clock path is tightly controlled with help

of a PLL device. The clock fan-out chips chosen are devices with multiple

signal level input compatibility, and output levels suitable for their

respective use, either LVDS or CML.

There are two

independent clock trees for the fabric clocks into all FPGAs. There is one common

MGT clock tree into all FPGAs. It carries the LHC based reference clock.

Segmented crystal clock trees allow for different bitrates on the incoming MGT

links and will in particular allow for an alternative line rate on tilecal

inputs. The control FPGA receives additional local clocks since it handles DAQ,

ROI, and control links as well.

The current L1Calo

modules receive their LHC bunch clock and associated data through the TTCDec

module, based on a TTCRx chip. Future LHC bunch clock distribution will differ

from this scheme. The jFEX will receive its timing information through the hub

modules, where the timing information will be re-formatted and thus shield the

jFEX from any changes in clock definition. The hub clock interface is compatible

to Xilinx MGT signals. The detailed protocol is defined by firmware only. The

hub links are defined in table x.

1.2.4

Configuration,

monitoring, and control

Pre-configuration

access / ATCA compliant slow control

The jFEX is a purely FPGA-based

ATCA module. All communications channels are controlled by programmable logic

devices and become functional only after successful device configuration. An

initial step of module initialization is performed by an IPMC device. It

communicates to the shelf via an I2C port (IPMB) available on all ATCA modules

in zone 1. The prospective ATLAS standard (LAPP IPMC / mini-DIMM format) will

be mounted on the jFEX. Additionally, the JTAG port in zone 1 will allow for

limited access to the module at any time. The signals are routed to the FPGA

components via an extension module.

Embedded

controller

A small, auxiliary

embedded controller will be available on the jFEX. It is Xilinx Zynq based. It will

allow for pre-configuration access and will be able to configure the processor

FPGAs. The device will boot off a microSD flash card.

FPGA

configuration

The baseline FPGA

configuration scheme on the jFEX is via the Zynq embedded controller. It will

configure the FPGAs from data stored on the microSD card. A local SPI memory

will allow for an alternative configuration method for the control FPGA. This

FPGA does not contain any algorithmic firmware and is therefore not expected to

be updated particularly often. The processor FPGAs will be configured off SD flash

memory, which is sequenced by the control FPGA.

In-situ configuration update will be possible via IP access to the

control FPGA. For debug purposes USB/JTAG configuration will be available as

well.

Environmental

monitoring

Board level temperature

and voltage monitoring will be a requirement. The default ATCA monitoring and

control path is via I2C links in zone 1. The backplane I2C port (IPMB) is

connected to the IPMC DIMM. On the jFEX configured FPGAs can be monitored for

die temperature and internal supply voltage. This is achieved by the use of

their built-in system monitor. These measurements will be complemented by

board-level monitoring points connected via I2C. The IPMB based monitoring is

meant to be used for basic functionality only. An additional path into the (IPbus

based) module control circuitry will complement the ATCA standard monitoring

scheme.

Module

control

On standard ATCA

modules, IP connectivity is mandatory for module control. This is generally

provided by two 10/100/1000 Ethernet ports on the backplane in zone 2

(redundant base interface). The respective lines are wired to the extension

module, where the required connectivity can be made to the IPMC, the embedded

controller, or to an MGT link on the control FPGA via an SGMII Phy device.

DAQ

and ROI

The jFEX will be able

to capture incoming, outgoing and internal real-time data and send them into

the readout stream. It will also be able to send region-of-interest data into

the 2nd level trigger.

The processor FPGAs

carry latency buffers which are used to store readout and ROI data. Upon

receipt of a level-1 accept signal the data are forwarded to de-randomizer

buffers, located on the processor FPGAs as well. These data are then serialized

onto the MGT backplane links (Zone 2 Fabric Interface) and routed to hub

modules in charge of further formatting and compressing the data. Due to lack

of handshake protocol the data volume to be read out of the processors will

have to be kept well below the bandwidth limits of the backplane channel, so as

to avoid any buffer overrun.

2

Functional

requirements

This section describes

the functional requirements only. Specific rules need to be followed with

respect to PCB design, component placement and decoupling. These requirements

are detailed elsewhere. For requirements on interfaces with other system

components, see section 5.

2.1

Signal

paths

The jFEX is designed

for high speed differential signal transmission, both on external and internal

interfaces. Two differential signalling standards are employed: LVDS and CML.

2.2

Real-time

data reception

Real-time data are

received optically from the back of the ATCA shelf; they are converted to

electrical representation, transmitted to the processors and de-serialised in

on-chip MGT circuits.

The requirements with

respect to data reception and conditioning are:

- Provide four 72-way MPO/MTP compatible

blind-mate fibre-optical backplane connectors in ATCA zone 3

- Route bare fibre bundles to 12-channel

opto receivers

- Supply opto-electrical components with

appropriately conditioned supply voltages

- Connect

single ended CMOS level

control lines to the control FPGA

- Provide suitable coupling capacitors for

multi-Gigabit links

- Run the signal paths into the processors

- Design the data paths such that

transmission rates up to 13Gb/s can be achieved

2.3

Real-time

data processing

The jFEX processing

resources are partitioned into six processors. This is a consequence of

limitations on MGT link count on currently available FPGAs. The requirements on

processing resources are not currently known. However, the envisaged algorithms

are expected to use a small fraction of logic resources only.

The requirements with

respect to the processors are:

- Process an area of 1.2 x 0.8 on each

processor FPGA, along with +/- 0.4 environment

- Provide

an input bandwidth and channel count sufficient to route an area

2.0 x 1.6 worth of calorimeter data into each processor FPGA

- Allow for additional connectivity in the

calorimeter overlap region

- Duplicate incoming data to neighbouring

FPGAs with PMA loopback scheme

- Process the real-time data : two sliding

windows algorithms (jet, tau) plus energy sums

- Transmit the jet and tau candidate data to

one of the processor FPGAs on parallel links

- Design the parallel data paths such that

transmission rates up to 1Gb/s can be achieved

- Merge the per-FPGA results on one of the

FPGAs

- Minimise latency on chip-to-chip data

transmission

- Provide 24 output fibres to be routed to

L1Topo. Line rate up to 13Gb/s per fibre.

2.4

Clock

distribution

Both the FPGA fabric and

the MGT links need to be supplied with suitable clock signals. Due to the

synchronous, pipelined processing scheme most of the FPGA-internal clocks need

to be derived from the LHC bunch clock or a device emulating it. Due to

requirements on MGT reference clock frequency accuracy, a mixed 40.00/40.08 MHz

operation is impossible. Therefore a requirement for 40.08 MHz operation has to

be introduced.

The requirements with

respect to the clock distribution on the main board are:

- Receive a clean LHC clock signal from the

backplane from each of the hub modules on the fabric interface Zone 2

- Allow for selection of either clock as a

system clock under firmware control (clock multiplexer)

- Allow for clock conditioning hardware in

the clock path (jitter control, multiplication)

- The LHC-based clock must be used for

reference on all real-time transmitters (to L1Topo)

- Provide the common LHC-based MGT clock to

all FPGAs

- Provide additional crystal-based MGT

reference clocks to all processor FPGAs for use on the receiver sections.

Allow for segmentation of the clock trees to cope with possibly different

line rates from various parts of the calorimetry.

- Connect the MGT clocks to the processor

FPGAs such that the central quad of 3 quads is supplied.

- Provide two fabric clocks to all FPGAs

(40.08 MHz crystal, LHC clock)

- Provide a separate crystal based MGT clock

to the control FPGA for use on the control link (Ethernet)

- Provide a separate crystal based MGT clock

to the control FPGA for use on the DAQ and ROI links

2.5

Timing command

distribution

A small set of timing

information is distributed to all detectors and the trigger system via the

communications channels of the TTC system. This information comprises the

Level-1 Accept signal, bunch count reset, broadcast commands and others. This

information is received on the jFEX from the hub modules via the backplane. The

data format is not yet fixed, but the data will basically comprise the full TTC

data stream, re-coded on a Xilinx MGT with 8b/10b encoding.

The requirements with

respect to timing distribution are:

·

Receive a

multi-Gigabit data stream on a single signal pair from the backplane fabric

interface from each of the hub modules

·

Route the

signals into the control FPGA

·

Allow

selection of either hub module as timing data source in firmware

·

Extract

the required data (L1A, BC reset, broadcasts) and route them on to the

processor FPGAs on parallel I/O

2.6

Configuration

and JTAG

JTAG is used for board

level connectivity tests, pre-configuration access, and module configuration.

During initial board tests and later hardware failure analysis, JTAG access

will be required to connect an automatic boundary scan system, generally when the

module is on the bench, not in an ATCA shelf. Also the initial configuration of

non-volatile CPLDs will be performed at that stage.

The requirements with

respect to boundary scan and CPLD configuration are:

- Allow for the connection of a boundary

scan system to all scannable components of the jFEX: FPGAs, CPLDs, and

mezzanine modules via standard JTAG headers, following the standard rules

on pull-up, series termination, and level translation between supply

voltage domains.

- Allow for CPLD (re)configuration,

following the boundary scan tests, and occasionally on the completed

system.

- There is currently no requirement nor

possibility known regarding integration of

devices sourcing or sinking MGT signals externally, into the

boundary scan scheme

The requirements with

respect to FPGA configuration are:

- Allow for static control of the FPGA

configuration port settings and read-back of the status via the control

CPLD.

- Provide SPI configuration of the control

FPGA according to the KC705 configuration scheme

- Connect an SD card to both the control

FPGA and the Zynq based controller

- Connect the serial configuration lines of

the processor FPGAs to user I/O of the control FPGA and the Zynq device to

allow for configuration off flash card data.

2.7

Module

control

On ATCA modules serial

protocols are used to achieve board level configuration and control. Typically

Ethernet would be used to control module operation. On the jFEX IPbus is used

to interface to the control FPGA, once it has been configured. IPbus is a small

footprint IP stack, implemented in firmware, based on standard Ethernet. All

board level control goes via the control FPGA. The control FPGA is in turn

connected to a Zynq based processor and to an ATLAS standard IPMC for low level

control and monitoring.

The requirements with

respect to general board control are:

- Provide eight-lane access from the base

interface in zone 2 to the extension mezzanine, compatible to 10/100/1000

Ethernet, so as to allow for an Ethernet Phy to be mounted on the

extension mezzanine module

- Provide for Ethernet connectivity onwards

to IPMC and Zynq

- Provide two-lane access from the mezzanine

on to the control FPGA (one MGT, bidirectional)

- Provide bi-directional connectivity

between processors and control FPGA

- Provide a control bus from the control

FPGA to all opto-electrical transceivers (I2C and static control)

- Provide a single ended and a differential

control bus from the control FPGA to the mezzanine module

- Provide an interconnect between control

FPGA and control CPLD (via extension module)

The CPLD

is in charge of mainly static controls that need to be asserted at power-up,

before the FPGAs are configured.

The

requirements with respect to the CPLD are:

- Communicate to the general board control

system via a bus to the control FPGA

- Control the static FPGA configuration

control lines

2.8

DAQ and

ROI

A single

lane for each DAQ and ROI transmission will be provided on each processor FPGA

on the jFEX.

The requirements with

respect to DAQ and ROI interface are:

- Connect each processor FPGA to the DAQ hub

via fabric interface in zone 2

- Connect each processor FPGA to the

ROI hub via fabric interface in

zone 2

- Run DAQ and ROI Data on the backplane

links at 6.4Gb/s, 8b/10b encoded

- Guarantee by choice of readout data that

local on-processor buffers do not overflow

2.9

Extension

mezzanine (X)

The extension

mezzanine provides some connectivity and real estate for control purposes. It

will be available on the jFEX prototype and might disappear on the production

modules, with the respective functionality integrated on the mainboard. The

requirements with respect to auxiliary controls on the mezzanine board are:

- Receive two 4-pair Ethernet signals from

backplane zone 2 (base interface)

- Connect to two Ethernet ports on the IPMC

- Connect the mezzanine to the control FPGA

via a single MGT for purpose of module control

- Connect the mezzanine to the control FPGA

via an LVDS level bus

- Connect the mezzanine to the control FPGA

via a CMOS bus for purpose of static and slow controls

- Connect the mezzanine to the control CPLD

- Connect the Zynq module via 32-way CMOS

level control bus

- Drive the MicroPOD control buses (I2C)

2.10

Zynq

module (Z)

The Zynq device might reside

on a mezzanine or on the main board. Its main use is the SD card based

configurator for the FPGAs. It will also be available for auxiliary controls

and house keeping

The requirements with

respect to the mezzanine board are:

- Wire the module to Ethernet via the

extension module

- Connect the module to an SD flash card

acting as processor boot device and configuration storage

- Connect a parallel buse to the control

FPGA for purpose of module control

- Connect the Zynq processor to a RAM chip

and some general I/O

2.11

IPMC dimm

A

“standard” ATLAS IPMC controller in mini-dimm format is used.

The requirements with

respect to the IPMC mezzanine board are:

- Connect to the ATCA zone-1 control lines

- Connect to the zone-1 JTAG pins via a

cable loop

- Connect to Ethernet via the extension

module

- Connect power control / alarm on the ATCA

power brick

- Supply the IPMC with the management

voltage generated on the power bridge

2.12

ATCA power

brick

A

“standard” ATCA power brick is to be used to simplify ATCA compliant power handling.

The requirements with

respect to the power brick are:

- 48/12V power brick

- ATCA power control / monitoring on-brick

- Internal handling of hot swap / in-rush control

- Internal management voltage generation

3

Implementation

This section describes

some implementation details of the jFEX module. This section will be expanded

before module final production.

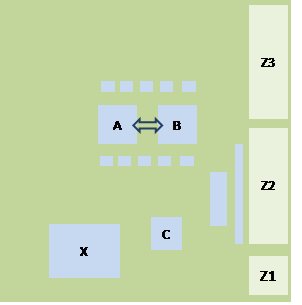

The jFEX is built in

ATCA form factor. The main board is

built as a ~20 layer PCB. The PCB is approximately 2 mm thick and will

fit ATCA standard rails. If required, the board edges would be milled down to

the required thickness. An initial floor plan is shown in Figure 5. The real-time data path is indicated.

Figure 5 – The jFEX floor plan

3.1

Real-time path

The

jFEX will require the largest FPGA devices available on the market. The design

is heavily I/O bound, since a large environment will need to be received for

each processor along with the “core” data.

Xilinx

XC7VX690T will be used on the prototype. At the time of writing it cannot be

ruled out that a larger device ( XC7VX1140T ) will be required to route

additional data from the calorimeter overlap region into the FPGA. Since this

device is not pin compatible there is a need to sort that issue out before

detailed module design is started.

The back panel

optical connectors provide a capacity of 288 fibres maximum, if four shrouds

are mounted. The back panel connection scheme has been chosen to simplify

maintenance on the module. However, in case of problems with the high density

fibre connectors, fibre bundles could alternatively be routed to the front

panel.

3.2

Clock

The

clock circuitry comprises various crystal clocks, a jitter cleaner for LHC

clock signal conditioning, and several stages of electrical fan-out. Various Micrel

device types are used to drive and fan out clocks of LVDS and CML type at low

distortion. All Micrel devices are sink terminated on-chip. The jitter cleaner

used on the jFEX is a Silicon Labs 5326. It

allows for jitter cleaning and frequency synthesis up to multiples of the bunch

clock frequency.

A

detailed block diagram of the clock path is shown in Figure 6.

Figure 6 – The jFEX clock distribution

3.3

Control

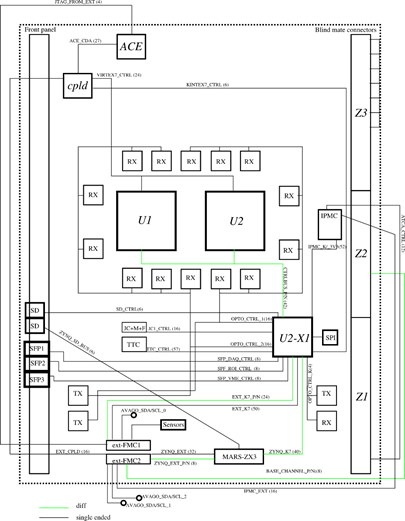

A detailed block diagram of control paths is

shown in Figure 7.

Figure 7 – The jFEX control paths

Module control

The jFEX module control is done via Ethernet access.

The required hardware components are available on the jFEX: an SGMII Phy

(M88E1111 or similar) is connected between the base interface in Zone 2 and an

MGT lane on the control FPGA. The firmware layer on top of the physical layer

will be the IPbus suite maintained by the University of Bristol. This scheme is

already in use on the topology processor L1Topo.

3.4

Board level issues: signal integrity, power supplies,

and line impedances

The jFEX is a large,

high-density module, carrying large numbers of high-speed signal lines of

various signal levels. The module relies on single-ended CMOS, and differential

(some or all of LVDS, PECL2.5, CML3.3, and CML2.5) signalling. System noise and

signal integrity are crucial factors for successful operation of the module.

Noise on operating voltages has to be tightly controlled. To that end, large

numbers of decoupling capacitors are required near all active components. FPGAs

are particularly prone to generating noise on the supply lines. Their internal

SERDES circuitry is highly susceptible to noisy operating voltages, which tend

to corrupt their high-speed input signals and compromise the operation of the

on-chip PLL, resulting in increased bit error rates. To suppress all spectral

components of the supply noise, a combination of distributed capacitance (power

planes) and discrete capacitors in the range of nF to hundreds of mF are required. On the FPGAs there are

capacitors included in the packages for decoupling of noise up to highest

frequencies.

The jFEX will receive

its MGT supply voltages from switching regulators. Current drawn on the MGT

supply lines was considered too high for linear regulators, if all links are

operated at full speed. The converters are equivalent to the ones used on

Xilinx evaluation modules, and the ripple, according to the specifications, is

well below the specified limits for the MGTs.

The jFEX base

frequency is 40.08 MHz. Parallel differential I/O operates at multiples up to

1Gb/s. Multi-Gigabit (MGT) links operate at 6.4 or 10+ Gb/s. This is only

possible on matched-impedance lines.

Differential sink termination is used throughout. All FPGA inputs are

internally terminated to 100Ω or to 50Ω||50Ω,

according to the manufacturer’s guidelines. All lines carrying clock signals must be treated with particular care.

There exists a checklist for the detailed module design.

4

Firmware,

on-line software and tests

The jFEX is an

entirely FPGA based module. For both hardware commissioning and operation a set

of matching firmware and software will be required. These two phases are well

separated and requirements differ considerably. Hardware debug and

commissioning will require intimate knowledge of the hardware components and

will therefore be in the hands of the hardware designers. Both firmware and

software will be restricted to simple, non-OO code. Hardware language is VHDL,

software is plain C. GUI based tools are not required and will not be supplied

by the hardware designers. Module commissioning from a hardware perspective is

considered complete once the external hardware interfaces, board level

connectivity, and basic operation of the hardware devices have been verified.

The hardware debug and commissioning will involve JTAG/boundary scan,

IBERT/ChipScope tests, and firmware/software controlled playback/spy tests with

any data source/sink device available. A multi-fibre output test module is

currently being designed at Birmingham University. Initially an L1Topo

prototype module will be available in the lab for test vector playback on a

small number of 12-fibre ports.

IPbus based module

control is being developed for the L1Topo processor and the required setup and

expertise will be available in the test lab. Also IPMC control will have been

explored on L1Topo by the time the jFEX prototype is available for first bench

tests. Backplane outputs provided for DAQ and ROI data transmission will be

tested for bit errors and link stability only. No specific data formats will be

tested on these links.

In parallel to the

hardware debug and commissioning, higher level software and firmware will be

developed for later operation of the jFEX. It will be possible to re-use

existent L1Topo firmware and software to a large extent.

The test environment

available in the home lab will allow for simple real-time data path tests only.

There is no hardware, software installation, nor expertise available to run any

tests involving DAQ/RODs/ROSes. Therefore all system level tests will have to

be done in an appropriately equipped L1(Calo) test lab. Currently the L1Calo

CERN test rig seems to be the only available option, before the jFEX can be

connected up at point 1.

4.1

Service- and infrastructure firmware

The correct operation

of high-speed (MGT) links and FPGA-internal clock conditioning circuitry is

prerequisite for any “physics” firmware running on the recovered data streams.

This service- and infrastructure firmware is closely tied to the device family

used. To a large extent the code is generated with IP core generator tools.

The bare MGT link

instantiations are complemented with code for link error detection and

monitoring, as well as playback and spy circuitry for diagnostics purposes.

These functions are controlled by the crate controller CPU, via IPbus, as

described above.

Real-time data are

copied to the DAQ via ROD links upon reception of a Level-1 trigger. These data

offer a further means of monitoring the correct functionality of the jFEX.

There exists an additional data path to the LVL-2 ROI builders for the purpose

of region-of-interest data transmission, as required.

All infrastructure

described above has been successfully implemented and operated for all L1Calo /

L1Topo processor modules. The detailed description is found in the collection

of documents referenced in section 1. All functionality will be re-implemented

on the jFEX. The JEM VHDL code is a purely behavioural description and can

therefore be re-used with just minor modifications. Some optimization for the

chosen FPGA devices might be desirable, but isn’t strictly required.

4.2

Algorithmic firmware

There are several

classes of physics algorithms currently being explored with help of physics

simulations. The energy summation is

expected to be simple and with low logic resource consumption. The jet sliding

window baseline algorithm will be similar to the algorithm used in run1, though

at slightly larger jet size and finer granularity.

Further algorithms

will be coded and simulated in the participating institutes. It is envisaged to

code and evaluate algorithms that are closer to current level-2 and offline jet

analysis. There will be a separate document on software and on algorithmic

firmware produced at a later date.

5

Interfaces

: connectors, pinouts, data formats

5.1

Internal

interfaces

The jFEX prototype module

carries three daughter modules: an IPMC module, a Zynq processor, and an

extension mezzanine.

The extension card is

connected via a 400-way Samtec connector (SEAM on the mezzanine module, SEAF on

the jFEX).

The Zynq based processor

is a small mezzanine.

The IPMC module is a

244-pin mini-dimm, mechanically compatible to DDR3 memory modules.

Documentation, including pinout is available from LAPP, Annecy.

5.2

Front

panel

The front panel shows

is carrying connectivity for both real-time output and non-real-time control:

Standard ATCA handle

switches and LEDs (from IPMC)

SD card slot

2 MPO connectors (from

MicroPODs, to L1Topo)

5.3

Backplane

connector layout

The backplane

connector is made to standard ATCA layout in zones 1 and 2. Zone 3 is populated

with four MTP/MPO connectors that connect onto a RTM with hermaphroditic

blind-mate shrouds (MTP-CPI).

5.4

Interfaces

to external systems

The jFEX interfaces to

external systems mainly via optical fibres. The physical layer is defined by the

fibre-optical components used. On the real-time data path fibre-bundles with

multiples of 12 multimode fibres are used. The external connections are made by

MTP/MPO connectors. The jFEX is equipped with male MTP connectors.

The calorimeter DPS

(and legacy) processors are connected via 72-way fibre assemblies, for the

L1Topo outputs 12-way assemblies will be used. Opto-electrical translation on

the real-time path is made with MicroPOD 12-channel transceivers. These devices

are fully compatible to MiniPOD devices, but offer higher design density. This

comes at the expense of custom-designed heat exchange and retention systems.

For the higher speed option (documented separately) a reduction in design

density is expected such that standard MiniPOD devices might be employed.

Data rates and formats

are defined by the FPGAs used for serialization and deserialization. For the

jFEX 6.4 Gb/s or 10+ Gb/s input data

rates will be supported. For the prototype module any rate up to 13 Gb/s will be

supported by the processor FPGAs, though maximum data rate will depend on the

exact device type being purchased in 2014. Mini/MicroPOD transceivers will (to

current data sheets) limit the data rate to a maximum of 14 Gb/s. It should be

noted that the Xilinx UltraSCALE device family is expected to be available in

time for final module production. Therefore the production modules might

slightly differ from the current design in terms of density and device count.

All real-time data

streams are used with standard 8b/10b encoding. The data links are assumed to

be active at all time. There are neither idle frames nor any packetizing of

data. For reason of link stability and link recovery an option of transmitting

zero value data words encoded into comma characters is being considered. This

might also simplify initial link start-up. A first attempt has been made to

define an encoding scheme for the L1Topo data links. The scheme will be used on

the jFEX as well.

The baseline

deserialization scheme is relying on a de-multiplexing the 6.4Gb/s data stream

to 4 sub-ticks (word slices) of 32 bits wide, transmitted on a 160MHz clock. It

is anticipated that data will need to be fully de-multiplexed to the LHC base

rate, since the algorithms require correlating all input data from all incoming

sub-ticks. Further information might have to be transmitted to identify

sub-ticks of the 40.08 MHz LHC bunch ticks. The de-multiplexing and word slice

alignment scheme is a firmware option and will not affect the design of the

interfacing processors. Compatibility to the data sources will be

guaranteed.

|

I/O |

From/to |

bandwidth |

|

|

|

Real-time

input |

DPS/legacy |

288 *

up to 13 Gb/s |

Opto

fibre / MTP 72 |

MicroPOD,

8b/10b |

|

Real-time

output |

L1Topo |

24 * up

to 13 Gb/s |

Opto

fibre / MTP |

MicroPOD,

8b/10b |

|

|

|

|

|

|

|

Control |

|

2*1Gb/s |

Ethernet

electrical, zone 2 |

|

|

|

|

|

|

|

|

DAQ |

D-ROD/hub |

6.4

Gb/s |

Zone 2 |

|

|

ROI |

R-ROD/hub |

6.4

Gb/s |

Zone 2 |

|

|

IPMB |

|

|

Zone 1 |

|

|

LHC

clock |

Hub/TTC |

|

Zone 2 |

|

Table 1

: external interfaces

5.5

Data

formats

The jFEX module is entirely

based on programmable logic devices. Therefore the detailed data formats do not

affect the hardware design of the module. At the time of writing this documents

data formats on the real-time interfaces are being defined and written up. A

preliminary input format …

6

Appendix -- will move to separate document?!?!?

6.1

Checklist

for detailed design

Detailed rules

regarding signal integrity are to be followed so as to make sure the high desity/high

speed module can be built successfully. In addition a few details on signal

wiring for FPGA control pins are listed. This list might be expanded for a

detailed design review.

The rules with respect

to power supply are:

·

Use

low-noise step-down converters on the module, placed far from susceptible

components.

·

Use local

POL linear regulators for MGT link supplies

·

According to the

device specifications the following supply voltages need to be applied to the

FPGAs: Vccint=1.0+/-0.05V, Vccaux=1.8V

·

On all FPGA supply

voltages observe the device specific ramp up requirement of 0.2ms to 50ms.

·

Run all

supply voltages on power planes, facing a ground plane where possible, to

provide sufficient distributed capacitance

·

Provide at

least one local decoupling capacitor for each active component

·

For FPGAs,

follow the manufacturer’s guidelines on staged decoupling capacitors (low ESR)

in a range of nF to mF

·

Observe

the capacitance limitations imposed by the voltage convertors

·

Minimise

the number of different VCCO voltages per FPGA to avoid

fragmentation of power planes

·

avoid

large numbers of vias perforating power and ground planes near critical

components

The rules with respect

to general I/O connectivity are:

·

Tie Vccaux

and most bank supplies to 1.8V. A given FPGA is supplied by only one 1.8 V

plane.

·

Use all

processor FPGA banks for LVDS (1.8V) only

·

Use HP

banks on the control FPGA for LVDS connections to the processor FPGAs and

mezzanine modules

·

For the

control FPGA only: wire a small number of banks for 3.3V single ended operation

(HR banks)

·

Neither

reference voltages nor DCI termination are required on the processor

FPGAs. Use respective dual-use pins for

I/O purposes

·

For the

control FPGA HR banks allow for DCI termination

on single ended lines

The rules with respect

to single ended signalling are:

·

Run FPGA

configuration and FPGA JTAG clock lines on

approximately 50 W point-to-point source terminated lines

·

Observe

the requirements on overshoot and undershoot limitation, in particular for

System ACE and FPGA JTAG and configuration lines. Use slew rate limited or low current signals and/or series

termination

The rules with respect

to differential signalling are:

·

For

discrete components, use internally sink-terminated devices throughout. Any

non-terminated high-speed devices need to be documented in a separate list.

·

Use LVDS

on all general-purpose FPGA-FPGA links

·

Use LVDS

on all GCK clock lines

·

Use DC

coupling on all LVDS lines

·

Design all

LVDS interconnect for 1Gb/s signalling rate

·

Use CML signalling

on all MGT lines, for both data and clocks

·

Design all

MGT data links for 10Gb/s signalling rate

·

Generally

use AC coupling on all MGT differential inputs and outputs, for both data and

clocks

- SFP devices might be internally decoupled,

microPOD transmitters might have a sufficient common mode range to allow

for direct connection

·

Use CML on

all common clock trees; rather than using AC coupling, observe the signalling

voltage and input compatibility rules as outlined by the device manufacturers

·

Use AC

coupling or suitable receivers when crossing voltage or signal standard domains, except on LVDS

·

Place

coupling capacitors close to source

·

Use bias

networks on AC coupled inputs where required

·

Route all

differential signals on properly terminated, 100 Ω controlled-impedance lines

·

Have all

micro strip lines face a ground plane

·

Have all

strip lines face two ground planes or one ground plane and one non-segmented

power plane

·

avoid

sharply bending signal tracks

·

minimise

cross talk by running buses as widely spread as possible

·

Avoid

in-pair skew, in particular for MGT links and clocks

·

Make use

of device built-in programmable signal inversion to improve routing

·

Avoid

impedance discontinuities and stubs, in

particular on MGT links and clocks

The rules with respect

to processor FPGA pre-configuration and configuration control pins are:

·

Wire

configuration lines for optional JTAG or slave serial configuration

·

Allow mode

lines M0, M2 to be jumpered to either Vcc or GND. Pre-wire to Vcc

·

Connect M1

to the CPLD (GND=JTAG mode, Vcc=slave serial)

·

Connect

PROGRAM, INIT and DONE lines to the CPLD

·

Pullup

DONE 330Ω, INIT 4k7 PROGRAM 4k7

·

Connect

Vccbatt to GND

·

Wire DIN,

DOUT and CCLK (series terminated) configuration lines to the CPLD

The rules with respect

to system monitor pins are:

·

Connect

DXN, DXP to I2C based monitoring circuits

·

Decouple

analog power and GND according to UG370 with ferrite beads and wire the system

monitor for internal reference (both Vref

pins to analog GND)

·

Do not use

analog sense lines Vn and Vp and connect to analog GND

6.2

Glossary

|

1000BASE‑SX |

Ethernet

optical (multimode) physical layer |

|

8b/10b |

Industry

standard data encoding scheme for purpose of DC balance and run length

limitation (bit change enforcement) |

|

ATCA |

Advanced TCA,

Advanced Telecommunications Computing Architecture |

|

Avago |

Manufacturer

of 12-channel opto-electrical transceivers. The Avago transceivers used on

THE JFEX are of MicroPOD type |

|

Base interface |

ATCA

compliant backplanes provide pre-defined redundant IP connectivity via

Ethernet 10/100/1000 from each slot to two modules in the crate (dual star) |

|

Fabric interface |

|

|

CML |

Current

Mode Logic, a high-speed differential signalling standard |

|

CTP |

The

Central Trigger Processor of ATLAS |

|

DAQ |

Data Acquisition

(link). |

|

|

|

|

L1Topo |

|

|

|

|

|

IBERT |

Xilinx

automated bit error rate test tool for MGTs |

|

IPMB |

Intelligent

Platform Management Bus (redundant, IPMB-A and IPMB-B), located in ATCA zone

1 |

|

JEM |

Jet – and

Energy module, being replaced by jFEX (continues to deliver tile signals) |

|

LVDS |

Low-Voltage

Differential Signaling standard |

|

MGT |

Multi-Gigabit Transceiver |

|

MicroPOD |

High

density 12-channel opto-electric transceiver |

|

MPO/MTP |

Industry

standard optical connector for fibre bundles,

here 12-72 fibres |

|

Phy |

A device

implementing the physical level (electrical representation) of a network

protocol |

|

Quad |

The

Virtex Serialiser/Deserialiser circuits

are arranged in tiles of four MGT links each |

|

ROI |

Region of

Interest, as signaled to 2nd level trigger |

|

RTDP |

Real-time data path, i.e. the data path going to the CTP. Latency critical path. |

|

RTM |

Rear

Transition Module (note: ATCA RTMs mate with the front modules directly in

Zone 3, not via the backplane) |

|

SGMII |

Serial

Gigabit Media Independent Interface (for Ethernet Phy), 1.25Gb/s |

|

|

|

|

|

|

|

|

|

|

Zone |

ATCA

connector zones 1 (mainly power), 2 (backplane data links), 3 (RTM

connections) |

6.3

Change log

2013